Virtual factories: Manufacturers use digital twins in the quest for a new industrial revolution

European companies form consortiums to develop technologies to design and simulate more efficient manufacturing processes

An electric shaver factory in Drachten, in the north of the Netherlands, is preparing for tests that will enable the European industry to thrive in increasingly competitive international markets. This factory, managed by the consumer electronics company Philips, is participating in a European Union-funded research project whose purpose is to encourage manufacturers to use digital twins, in other words, virtual factories created with technologies designed to optimize current production processes.

The idea is to use techniques like cloud computing, artificial intelligence, robotics and blockchain technology to create models of manufacturing processes and identify areas for improvement. “The industry is experiencing a transition phase and digital technologies can help,” says Cécile Girardot, coordinator of the DIMOFAC initiative, which will run until March 2024: “Digital twins provide real-time data that can show the performance of machines in the real world on a virtual plane.”

Europe’s €5 billion ($5.4 billion) manufacturing sector, with global powerhouses in areas such as aviation, steel, automotive and chemicals, must grapple with export-oriented manufacturers abroad and more stringent environmental standards within the European Union. These two underlying challenges are compounded by spikes in energy prices following the Russian invasion of Ukraine in February 2022 and supply chain disruptions triggered by the Covid pandemic two years earlier.

The EU has set up a €1.15 billion ($1.25 billion) public-private partnership called Factories of the Future to promote research and innovation in the field of manufacturing, which illustrates the importance of this issue on the EU’s political agenda. What is on the line is the ability of European companies to adapt to what has been dubbed the fourth industrial revolution, or Industry 4.0, an era characterized by automation and connectivity.

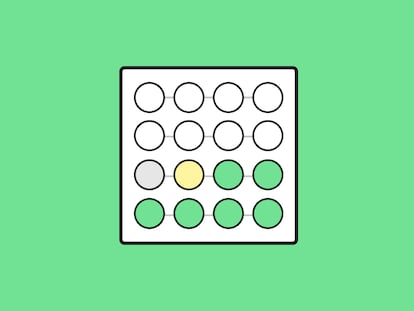

The virtual factory concept is increasingly gaining ground in Europe. The aeronautics company Airbus and the electrical equipment specialist Schneider Electric are exploring digital twin concepts and establishing virtual production plants. Since it launched in late 2019, DIMOFAC has developed a system to streamline manufacturing processes called plug-and-produce, which enables the reconfiguration of production lines by connecting real machinery to their corresponding digital twins.

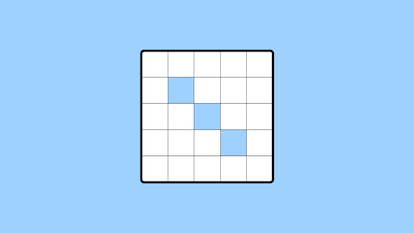

Using this system, a manufacturer can simulate a new configuration virtually and resolve any problems online before installing the equipment in a physical factory. Production problems may arise, for instance, if recycled raw materials are used whose properties are not always identical, as Girardot, who coordinates European projects on advanced materials and manufacturing at the French research institute CEA-Liten, explains: “In these cases, it is necessary to adapt production. The sooner this is done, the better. The main objective is to reduce the time required for reconfiguration.”

The project’s plug-and-produce system will be piloted in five existing production plants across Europe. Alongside electric shavers in the Netherlands, there are aerospace components fabricated by Éirecomposites in Ireland and interactive screens produced by Schaltag in Switzerland. This technology is being implemented at all five sites and results are expected within the first quarter of 2024. DIMOFAC has succeeded in bringing together a wide range of industrial expertise thanks to its 30 partners, including Siemens Industry Software (France), mechanical engineering company FILL (Austria) and EXOM Engineering (Spain).

Improved coordination of design and manufacturing

Another EU-funded project, FIRST, which has brought the future of digital factories a step closer, has explored how digital factories can increase efficiency in production facilities spread across multiple locations. The new designs and processes developed by FIRST will enhance collaboration, said Lai Xu, coordinator of the initiative, which concluded in December 2022 after six years in operation. “In the past, production plants were often quite isolated,” says Xu, who is also an associate professor at Bournemouth University (U.K.) and works on collaborative business processes and virtual enterprises.

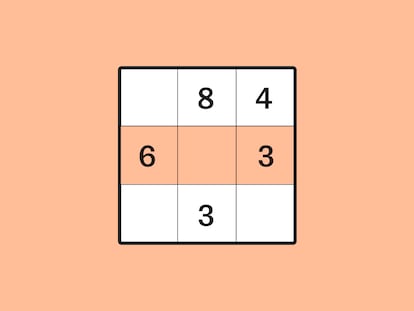

According to Xu, the focus of FIRST was to identify the stumbling blocks and obstacles that could hinder the use of virtual factory technologies and to develop strategies to address them. The project partners (seven in total) were manufacturers, software companies and universities and came from countries such as Germany, Italy, the Netherlands and China. Xu is optimistic about the potential that digital twins can offer the industry on business and environmental levels. As an example, using a digital model of the entire production process, a company could design a pair of shoes in Paris or Milan and then coordinate their manufacture and sale on a global stage.

By making use of blockchain technology, an IT network could connect all stakeholders (stores, designers, logistics companies and manufacturers) and send them information about exactly what is needed, where and when. “A tailor-made shoe can be designed in one place and manufactured in another, resulting in a more efficient and flexible manufacturing process and a reduced environmental impact,” explains Xu. Virtual factory technologies do not require an all-or-nothing approach. Manufacturers can embrace some aspects to improve processes without having to commit to a comprehensive implementation. This may be particularly valuable for many small and medium-sized companies in the European manufacturing sector, which do not have the resources to completely overhaul their systems.

Virtual factory technologies can also help companies more efficiently manage the maintenance processes of complex machinery, leading to cost savings. “Sensors around the machines collect data that permit programming when an engineer should be dispatched to repair them,” says Xu. As proof of the ever-growing importance of virtual manufacturing technologies, the FIRST coordinator says that the consortium is seeking funding from the EU and other countries to achieve further advances in this field.

The research described in this article has been supported by EU funds. This article was originally published in Horizon, the European Union Magazine for Research and Innovation.

Sign up for our weekly newsletter to get more English-language news coverage from EL PAÍS USA Edition

Tu suscripción se está usando en otro dispositivo

¿Quieres añadir otro usuario a tu suscripción?

Si continúas leyendo en este dispositivo, no se podrá leer en el otro.

FlechaTu suscripción se está usando en otro dispositivo y solo puedes acceder a EL PAÍS desde un dispositivo a la vez.

Si quieres compartir tu cuenta, cambia tu suscripción a la modalidad Premium, así podrás añadir otro usuario. Cada uno accederá con su propia cuenta de email, lo que os permitirá personalizar vuestra experiencia en EL PAÍS.

¿Tienes una suscripción de empresa? Accede aquí para contratar más cuentas.

En el caso de no saber quién está usando tu cuenta, te recomendamos cambiar tu contraseña aquí.

Si decides continuar compartiendo tu cuenta, este mensaje se mostrará en tu dispositivo y en el de la otra persona que está usando tu cuenta de forma indefinida, afectando a tu experiencia de lectura. Puedes consultar aquí los términos y condiciones de la suscripción digital.