Piñor: the Spanish ‘coffin town’ that cannot produce caskets fast enough

The coronavirus crisis has flooded this Galician village with new orders and revitalized an industry that was suffering from Chinese competition

Three generations ago, the residents of Piñor, a village of 1,176 souls in the northwestern Spanish region of Galicia, decided to use the surrounding pine forests to make wooden coffins. The villagers figured that their line of business would benefit from stable demand, free from the ups and downs of the furniture sector. It might even experience exponential growth in the event of wars, natural disasters or epidemics.

But the coronavirus pandemic struck at a time when several local entrepreneurs had already retired, while others were struggling to compete with the unbeatable prices of Chinese-made caskets, which are favored by funerary services and insurance companies over higher-quality national products.

If we were able to make 500 caskets a day, they’d get soldJoaquín Vázquez, coffin manufacturer

These days Piñor, the village that makes a living out of death, has suddenly found itself overwhelmed by the demand for coffins. The massive imports of chipboard caskets for under €100 have slowed down, and traditional manufacturers from Galicia now find themselves out of stock and flooded with orders that will keep them busy at least until the month of August.

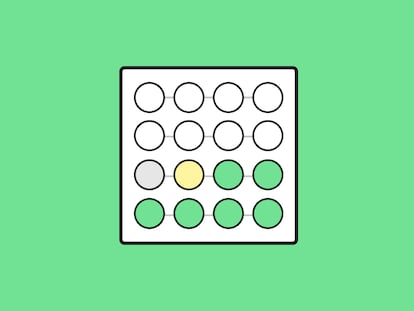

Of the 13 factories that once operated in Piñor before competition from China eroded the sector, there are nine left. The industry leader is Ataúdes Gallego, which boasts the highest number of exports and has also pioneered an “ecological” casket made with more biodegradable components.

In order to cope with the spike in demand caused by the coronavirus crisis, manufacturers have expanded workers’ shifts and doubled their production. They have also adapted their factories to the current emergency, producing “basic model” coffins meant for cremation.

“They have flat lids, smooth sides and wooden handles. They feature water-based varnish and have no iron or glass parts, or mouldings of any kind,” says the mayor of Piñol, José Luis González Rodríguez, who also runs one of the local factories and is additionally the vice-president of Ataugal, the Association of Coffin Manufacturers of Galicia.

While coffin makers continue to thrive in the current scenario, other related businesses such as wreath makers are experiencing a slump because the strict confinement measures have banned wakes and large funerals for the deceased.

“We are doubling shifts and extending them into the weekend,” confirms Joaquín Vázquez, the owner of a factory in Ribadavia, near Piñor. The same number of workers are putting out twice as many caskets despite the fact that the new safety protocols are slowing down their work. “If we were able to make 500 caskets a day, they’d get sold,” says Vázquez.

Demand in Spain has spiked so much that the effects are being felt in nearby Portugal. In Chaves, a Portuguese town located 20 kilometers from the border with the Galician province of Ourense, a Galician entrepreneur named María Chao has quadrupled her production by hiring more personnel and adding weekend shifts. During the first three weeks of confinement, her factory shipped 3,500 coffins to Madrid.

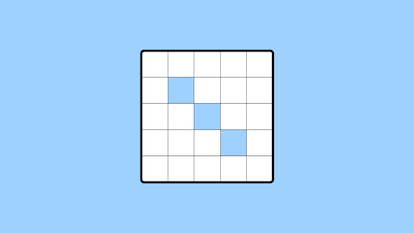

Meanwhile, funerary companies were concerned that they might run out of coffins and started purchasing as many as they could. If Piñor’s midsize factories were producing 200 caskets a month, they are now manufacturing 400 and employees have worked right through the Easter holidays in order to serve “our lifelong clients first, then the new ones.”

We don’t use any material from outside Spain save for the wood, which comes from Ivory CoastJosé Luis González, coffin maker

The mayor of town says that the coronavirus crisis could be something of a wake-up call for the industry, which is now demanding “Galician materials” instead of Asian products, which are at least six times cheaper than the most basic coffins made in Spain.

Funerary companies “have always had enough of a [profit] margin” to buy locally-produced coffins, says the mayor, noting that the dirt-cheap coffins have not reduced the bill that families of the deceased pay for the services.

“We don’t use any material from outside Spain save for the wood, which comes from Ivory Coast,” says José Luis González, who inherited the business from his father, “who sculpted saint figures.”

In Piñor, the first coffin manufacturer had apprentices who in turn set up their own factories and hired workers, who later started businesses of their own as well. Eventually, every family in the village became involved in the sector.

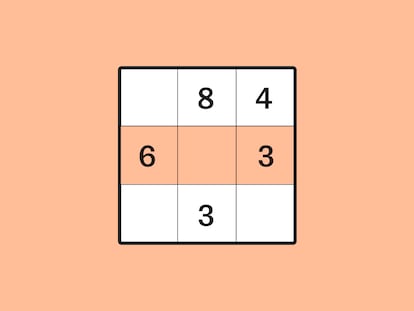

Although some producers still work with chestnut and poplar, most of them now use a very soft wood from the kapok tree that grows in West Africa and is known as fromager or ceiba in Spain. “The rest is made in Spain,” says González Rodríguez. “The fromager is curved in Valencia, the Christ figures are from Murcia, the varnish comes from Logroño, the padding from A Estrada (Pontevedra), the base of the coffin is made in Santiago and the staples come from Bilbao.”

For now, nobody in Piñor has contracted the coronavirus. Agents from the Civil Protection service run errands for anyone who requests the service in this village of elderly residents. The agents go to “the butcher’s, the supermarket, the pharmacy, to pick up prescriptions...” explains the mayor. Residents have also been given face masks and gloves, as well as the mayor’s cellphone number to dial in the event of any emergency.

At the factories, when outside trucks come to pick up a new order, drivers are instructed to remain inside their cabins. Factory workers load the coffins and the drivers go on their way without technically setting foot in town. Over at Joaquín Vázquez’s factory, according to the EFE news agency, it’s been weeks since anybody from outside the company walked into the premises. Inside, workers keep their distance, change their clothes in a different area, and the factory is disinfected “twice a day.”

English version by Susana Urra.

Tu suscripción se está usando en otro dispositivo

¿Quieres añadir otro usuario a tu suscripción?

Si continúas leyendo en este dispositivo, no se podrá leer en el otro.

FlechaTu suscripción se está usando en otro dispositivo y solo puedes acceder a EL PAÍS desde un dispositivo a la vez.

Si quieres compartir tu cuenta, cambia tu suscripción a la modalidad Premium, así podrás añadir otro usuario. Cada uno accederá con su propia cuenta de email, lo que os permitirá personalizar vuestra experiencia en EL PAÍS.

¿Tienes una suscripción de empresa? Accede aquí para contratar más cuentas.

En el caso de no saber quién está usando tu cuenta, te recomendamos cambiar tu contraseña aquí.

Si decides continuar compartiendo tu cuenta, este mensaje se mostrará en tu dispositivo y en el de la otra persona que está usando tu cuenta de forma indefinida, afectando a tu experiencia de lectura. Puedes consultar aquí los términos y condiciones de la suscripción digital.