Meat without slaughter? Three eco-friendly alternatives are on the table

Investment in food that resembles animal products has soared in recent years, although the technological challenges are still significant

In 1798, British clergyman Thomas Malthus stated that humanity was doomed to recurring periods of famine and suffering as population growth would always outstrip the amount of food produced. His analysis was correct given the historical data it was based on, but he failed to foresee the transformation of the world – one that began during his own lifetime.

The steam engine, invented years earlier, the advent of electricity that began shortly after, and the creation of chemical fertilizers at the beginning of the 20th century all combined to make it possible to increase the supply of food and other natural resources to sustain what is now almost eight billion people on this planet. The growth of the population and the increase in the resources consumed by each individual, however, has had the kind of environmental impact that threatens to prove Malthus right, albeit a few centuries late.

One of the threats to the world’s ecological balance is meat production. According to a report by the UN Food and Agriculture Organization (FAO), 14.5% of global CO₂ emissions are linked to livestock farming; to this must be added deforestation to expand fodder crops, the disposal of waste and the suffering of livestock.

To limit such an impact, one solution would be to reduce meat consumption. But while it remains to be seen whether raising awareness will lead to a sufficiently significant reduction in consumption, the machinery that combined science, technology and capitalism to discredit Malthus’ predictions circa 1798 is already working to generate alternatives that will allow us to continue enjoying meat while reducing its adverse effects on the environment. The most optimistic long-term scenario is a meat industry without animals. This may sound as far-fetched as a car industry without combustion engines did a few decades ago, though the European Union intends to make that a reality by 2035.

A €250,000 hamburger

The production of imitation meat has come a long way since 2013, when Maastrich University researcher Mark Post presented an artificial hamburger costing €250,000. Seren Kell, director of science and technology in Europe at the non-profit organization The Good Food Institute (GFI), explains that despite the existence of very valid alternative proteins from a dietary point of view, such as legumes, the creation of products that mimic the meat experience is useful, at least to facilitate a transition to a world in which less is consumed.

“Regarding winning over consumers, the goals are taste, price and ease of access,” says Kell. GFI’s objectives include reducing animal suffering and climate change. “It’s about making products that are easy to integrate into the diets of many people, without having to be particularly creative as a cook,” she adds. “So, if you have products that imitate what people are used to eating, it’s easier for them to change at least part of their diet based on animal protein.”

Up to now, some of the most spectacular results have been with plant-based meat substitutes. Meat grown from cells extracted from animals and multiplied in bioreactors aims to create products similar to hamburgers or sausages. However, in Israel, where this technology is at its most advanced, the company Redefine Meat has produced complete steaks, which try to recreate the texture and flavor of a real steak, using 3D printing technology in which the raw materials are soybeans, peas, beets and coconut oil. This meat will be on the menus of some European restaurants in the coming months. In Spain, the Navarre-based company Cocuus is working on the development of similar products.

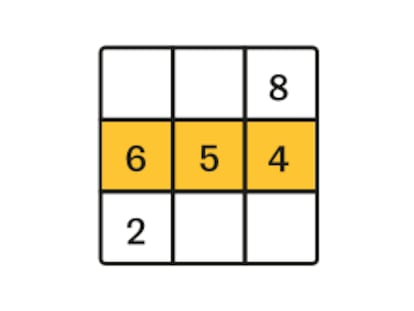

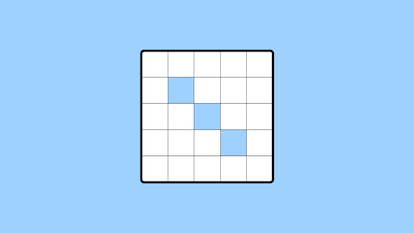

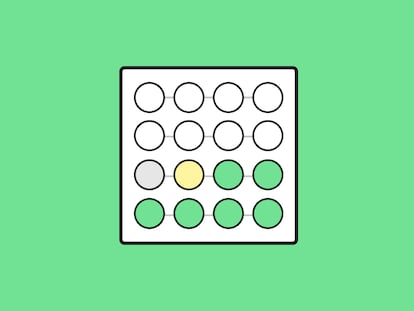

Of the $3 billion (about €2.66 billion) that GFI says companies dedicated to meat alternatives in 2020, around $2.2 billion was spent on those working with plants. In second place, with an investment of just over $500 million, were companies that produce proteins using fermentation, using a process similar to that used in beer-making whereby microbes transform waste from the agricultural industry.

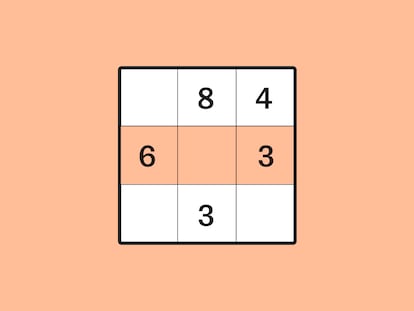

Five billion cows

Bosco Emparanza, CEO of MOA Foodtech, explains how microbes are capable of transforming plant waste from the agri-food industry into cheap and nutritious protein. “We have worked with Barilla [an Italian pasta manufacturer] to transform pasta waste to produce protein,” he says. “It is currently used to feed pigs and cows, but we give it to a microorganism that converts it into protein in a much more efficient way, using 98% less water and generating 85% less CO₂ than cows. Cultured meat is in its initial stages. There will be a transitional phase and we want to be part of that transition,” he adds.

Marco Bertacca, CEO of Quorn Foods – another company dedicated to fermentation – has calculated that if the eight billion tons of carbohydrate waste produced by agriculture each year could be processed with these technologies, we would obtain “the same amount of protein that we would obtain from five billion cows [...], three times more than there are on the planet right now.” Converting a small fraction of this waste would make a significant difference in reducing the carbon footprint associated with food production.

Whether through plant-based proteins that have been known to us for thousands of years or those obtained by other means and prepared to imitate meat, there are alternatives when it comes to eating more sustainably, which also means reduced animal suffering and, in some cases, a healthier diet. However, as is often the case with food, being aware of what is good for us does not necessarily reduce the temptation to make less healthy choices, such as polishing off that tub of ice cream or giant bag of potato chips. For those who crave an authentic steak, cultivated meat is of particular interest. With just over $300 million invested in 2020, this area is less advanced than plant-based or fermented substitutes, but it would be a way to produce real meat without killing animals.

Cultured or lab-grown meat is obtained by harvesting cells from muscle fibers, called myocytes. These cells can be cultured in a bioreactor to artificially create the meat that animals produce in their bodies. The cultures would be useful for producing things like minced meat to make hamburgers or sausages, but there are still many challenges ahead.

One challenge consists of adding other cells such as fat cells to make the meat tasty or generating the structures needed to shape the meat to resemble a specific cut. It is also necessary to find substitutes for the growth factors that are still needed to make meat proliferate in a lab and which account for a large part of the cost of production. For these and other reasons, experts such as Ricardo San Martin of Berkeley University are skeptical that large-scale production of laboratory meat will ever become economically viable. “If you have a thousand cells, there are a thousand things that can go wrong,” he says.

Lab-grown meat skepticism

Javier Carballo, a professor of food technology at the University of Vigo in Spain’s northwestern Galicia region, believes that “properties identical to those of conventional meat will never be achieved, much less a product with the texture and sensory complexity of a T-bone steak, for example. People would have to get used to these new products and forget the old ones, which is not easy, either in the short or medium term,” he adds.

“I don’t believe that 100% of animal meat will be replaced, because people like it and there are very good producers, but we have to consume differently, reducing the amount we eat, which is clearly excessive, and take advantage of alternatives,” adds Emparanza.

In Carballo’s opinion, the best-case scenario after overcoming the technological challenges to achieve products similar to those of ordinary meat, would be that “the product becomes just another option on the market – more expensive but not healthier than conventional meat and accessible only to a minority.” He calculates that, optimistically speaking, it could replace 20% or 25% of human meat consumption. But whatever the outcome, he agrees with other experts that “we should consume less red meat, whether conventionally raised or cultured.”

Questions of scale or the origin of growth factors are not impossible problems to solve. They are just technical questions that require, among other things, adequate fundingSeren Kell, The Good Food Institute

Seren Kell acknowledges these challenges, but points out that intensive work in this area “started just five or six years ago and yet we already have more than 100 startups worldwide and new proof-of-concepts popping up every few months. Questions of scale or the origin of growth factors are not impossible problems to solve. They are just technical questions that require, among other things, adequate funding,” she says. From her point of view, unlike other areas such as renewable energies, which has enjoyed tens of millions of euros in investment, countries have not been involved in boosting these technologies on a significant scale. “Some assessments estimate that [these types of technologies] would produce meat with 90% less greenhouse emissions, besides reducing water pollution and land use. That extra land could be used for carbon capture projects or wilderness restoration initiatives to improve the environment and biodiversity,” adds Kell.

As the recent controversy over macro-farms has shown, the meat debate is politically charged and it will be important to consider how people in the meat industry will adapt, not to mention what would happen to all the animals that are bred to satisfy our appetites. In the Netherlands, the country with the most livestock head per capita in Europe, the government announced a €25 billion, 13-year plan to reduce its livestock and the huge amount of manure it generates. The money will be used to retrain livestock farmers to work in other sectors and to switch from intensive to extensive livestock farming. The measure was harshly criticized by several farming collectives in the country.

In the coming decades, the debate on how to produce meat and how to consume it will intensify. Those who trust that human ingenuity will once again defeat predictions of doom based on past trends that do not take into account new technologies will be challenged by those who favor a strategy of austerity when it comes to limiting the havoc we are wreaking on our exhausted planet. An animal-free meat industry may be part of the solution to a problem that will require exploring all avenues.

Tu suscripción se está usando en otro dispositivo

¿Quieres añadir otro usuario a tu suscripción?

Si continúas leyendo en este dispositivo, no se podrá leer en el otro.

FlechaTu suscripción se está usando en otro dispositivo y solo puedes acceder a EL PAÍS desde un dispositivo a la vez.

Si quieres compartir tu cuenta, cambia tu suscripción a la modalidad Premium, así podrás añadir otro usuario. Cada uno accederá con su propia cuenta de email, lo que os permitirá personalizar vuestra experiencia en EL PAÍS.

¿Tienes una suscripción de empresa? Accede aquí para contratar más cuentas.

En el caso de no saber quién está usando tu cuenta, te recomendamos cambiar tu contraseña aquí.

Si decides continuar compartiendo tu cuenta, este mensaje se mostrará en tu dispositivo y en el de la otra persona que está usando tu cuenta de forma indefinida, afectando a tu experiencia de lectura. Puedes consultar aquí los términos y condiciones de la suscripción digital.