The gyroid: A mathematical fantasy that recreates natural wonders thanks to 3D printing

Industries are embracing these geometric shapes, which were imagined in 1970 by a NASA scientist. Decades later, they have been observed inside butterfly wings and other ultralight biological structures

During the 1960s, NASA was searching for new, lightweight and strong structures for its aircraft. They had to be strong enough to withstand the launch process and the conditions of outer space, but also as light as possible to minimize fuel costs.

In 1970, one of the scientists on the research team, Alan Schoen, described a novel geometric shape, which he dubbed the “gyroid.” Its unique geometry met the space agency’s objectives. However, manufacturing it was too complex, given the limited tools available at the time.

Today, thanks to 3D printing, it’s now possible to create this mathematical shape, which has been used in the design of acoustic panels, bone implants and works of art.

Gyroids are minimal surfaces: they have zero mean curvature. That is, at every point on the surface, the sum of certain values called “principal curvatures” is zero. This geometric concept can be seen, for example, in the sinuous shape of soapy liquid, when a circle-shaped wire is immersed in it.

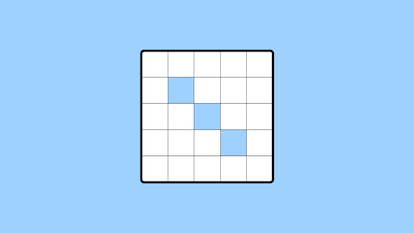

Furthermore, gyroids are triply periodic, meaning that they repeat in three spatial directions. This allows for the construction of a “composite” gyroid shape, repeating the original shape as many times as desired, in all three directions. On the other hand, gyroids don’t contain straight lines and cannot be divided into symmetrical parts, making them particularly difficult to visualize. Until recently, constructing them was also tremendously complicated.

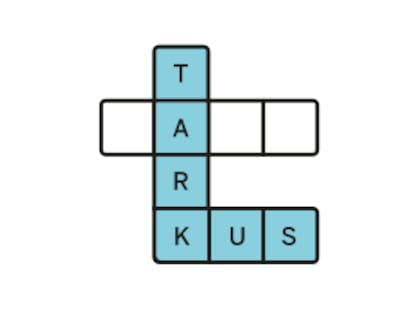

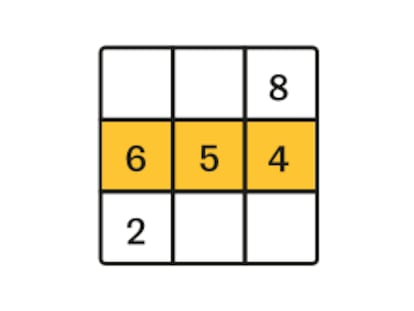

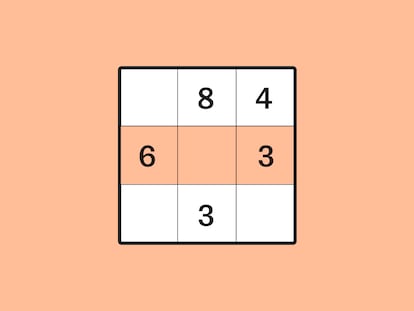

Additive manufacturing — popularly known as 3D printing, which began to develop in the 1980s — has made it possible to create gyroids for the first time. To print a gyroid, you must first design it digitally by using the mathematical formula that describes it, and then send the instructions for manufacturing it to the printer. The exact formula for a gyroid is very complicated, but it can be approximated using a simple equation that only involves trigonometric functions, multiplication and addition: sin(x)cos(y) + sin(y)cos(z) + sin(z)cos(x) = 0.

Depending on the intended application, gyroids can be made of plastic, ceramic, concrete, or even metal. Metal printing is somewhat different from conventional printing: a laser melts the desired shape and fuses it, layer by layer, over another layer of very fine metal powder. Because complex designs can be mass-manufactured, the desired properties can be maintained (thanks to the constructed structure) by using easily-obtained metals. This avoids the use of expensive and geostrategic metals, such as rare earth elements (REEs). The result is more sustainable, precise, complex and robust parts.

From a structural point of view, the gyroid has very interesting properties. First, it has great mechanical strength. A useful analogy is that of a sheet of paper: it doesn’t support much weight, but if rolled into a tube, it can withstand a much greater load along its longitudinal axis. Something similar happens with gyroids: by bending surfaces along all three axes, a structure that supports greater loads is achieved. With this design, the construction supports the same weight with less material, in a structure made up of lighter elements.

Nature discovered them first

Another characteristic of the gyroid is that it has a high specific surface area: the complex geometry of the recesses in the composition generates a large surface area per unit volume. This makes them optimal as heat exchangers, since the larger the contact surface, the more efficient the process of heat transfer.

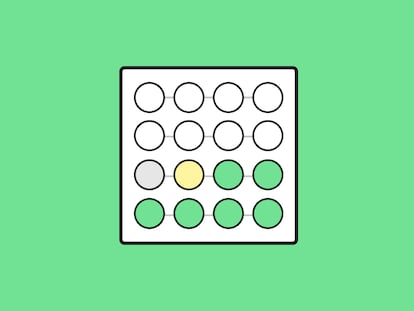

Gyroids have been used in various industrial designs, from acoustic panels to mail packaging to shoe insoles, and even in artistic works. They’ve also been used in biomedicine. Gyroids almost exactly replicate the internal bone structure of humans: not only do they resemble their shape, but they’re also capable of supporting weight. Meanwhile, gyroid hollows allow osteoblasts — the cells responsible for bone regeneration — to proliferate rapidly. Furthermore, if made from a biodegradable material, they can be safely integrated into a patient’s body.

Decades after Schoen’s mathematical discovery of gyroids in 1970, gyroids began to be found in nature: they’ve been observed in the mitochondria of cells and butterfly wings, as well as in the porous, lightweight structure of human bones. This is yet another example of how evolution has a leg up on humanity when it comes to finding the best design. Through research, scientists simply end up rediscovering it.

Ana López-Terradas is an industrial engineer and manager of the Spanish National Research Council’s (CSIC) additive manufacturing platform (FAB3D) at the National Center for Metallurgical Research (CENIM).

Jon Gurutz Arranz Izquierdo is a science journalist with a grant from the CSIC-BBVA Foundation Awards for Scientific Communication.

Ágata Timón García-Longoria is the coordinator of the Mathematical Culture Unit at Spain’s Institute of Mathematical Science (ICMAT).

Sign up forour weekly newsletterto get more English-language news coverage from EL PAÍS USA Edition

Tu suscripción se está usando en otro dispositivo

¿Quieres añadir otro usuario a tu suscripción?

Si continúas leyendo en este dispositivo, no se podrá leer en el otro.

FlechaTu suscripción se está usando en otro dispositivo y solo puedes acceder a EL PAÍS desde un dispositivo a la vez.

Si quieres compartir tu cuenta, cambia tu suscripción a la modalidad Premium, así podrás añadir otro usuario. Cada uno accederá con su propia cuenta de email, lo que os permitirá personalizar vuestra experiencia en EL PAÍS.

¿Tienes una suscripción de empresa? Accede aquí para contratar más cuentas.

En el caso de no saber quién está usando tu cuenta, te recomendamos cambiar tu contraseña aquí.

Si decides continuar compartiendo tu cuenta, este mensaje se mostrará en tu dispositivo y en el de la otra persona que está usando tu cuenta de forma indefinida, afectando a tu experiencia de lectura. Puedes consultar aquí los términos y condiciones de la suscripción digital.