Chinese researchers create mutant worms that make spider silk

Scientists have introduced arachnid genes into silkworms to produce threads as strong as nylon and six times tougher than Kevlar

Chinese researchers have genetically modified silkworms to produce spider silk. The threads from these silkworms combine the mechanical properties of synthetic fibers such as nylon, which is one of the most resistant, and Kevlar, a material used in bulletproof vests. The authors of the work, published in the scientific journal Matter, believe that the mass production of spider silk could be an alternative to synthetic materials, which — due to their resistance — become an environmental problem when they reach the end of their use.

Silk production is a wonder of nature that humans have taken advantage of. Millennia ago, somewhere in East Asia, specimens of the wild silkworm (Bombyx mandarina) began to be bred in captivity. In the process of domestication, the silkworm moths lost the ability to fly, and began to depend on its breeders to feed them white mulberry leaves. The domestic silkworm (Bombyx mori) had been created. The moths cannot fly, but they are still magnificent animals. A moth can lay hundreds of eggs containing tiny worms measuring just a few millimeters. When these worms emerge from the egg, they increase their size 40-fold in about six weeks. Then, they stop eating and their head becomes bigger. With the moment of metamorphosis nearing, the worm secretes a silk thread from its head, spinning to create a cocoon. At this point, the sericulturists boil the cocoons, with the chrysalis inside, and after a drying process, unravel it. The fiber can exceed 1,000 meters in length. The silk is shiny, light, very soft, breathable, biodegradable and relatively resistant, but it lacks other mechanical properties that have limited its use to the textile industry, some medical applications and little else.

Now, researchers from several Chinese universities argue that it is possible to create silk as resistant to tension as nylon fishing lines and as hard as Kevlar, another synthetic material known for its strength. To achieve this goal, they turned their attention to spiders. Like the B. mori silkworm, most of the 41,000 known arachnid species produce silk. And some, like Darwin’s bark spider, which inhabits the shrinking jungles of Madagascar, make the toughest animal fiber ever detected. In physics, toughness refers to a material’s ability to withstand deformation until it breaks. Both worm and spider silk are natural polyamides, while, nylon and Kevlar are synthetic polyamides. The latter have brought great benefits to society, but they are among the biggest polluters due to their durability, and sustainable substitutes need to be urgently found.

With this in mind, the Chinese scientists considered the possibility of producing spider silk. Except for some tests in the laboratory, mass production of spider silk appeared seemingly impossible: no species of spider has been domesticated, which would allow certain traits to be selected. Additionally, spiders are territorial and tend to eat one other. For these reasons, large-scale breeding of spiders did not seem to have much of a future. The other option was to turn to genetics, and that is what the scientists decided to do.

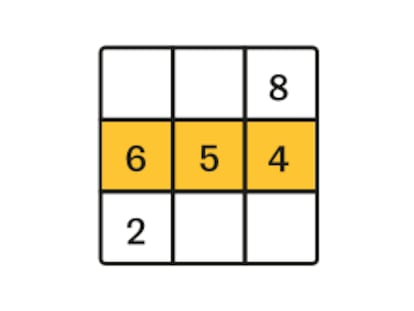

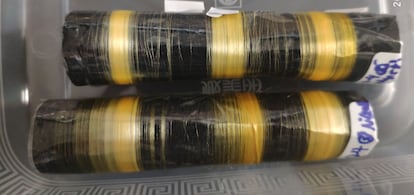

Using CRISPR gene editing technology, they inserted genes that express spider silk proteins into the secretory glands with which the silkworm creates its own. They did this with microinjections, while the silkworms were still inside the eggs. After hatching, they were allowed to complete their life cycle until, in the moth phase, they mated with other, non-genetically modified moths. From the next generation, the researchers selected several worms, some of them mutants. They were all capable of secreting silk. When the scientists forced the silkworm to spin the silk (see image above), they analyzed it to determine its chemical structure and mechanical properties.

The silk thread from the mutant worms showed “an impressive tensile strength (1.3 GPa) and toughness (300 MJ/m³), surpassing Kevlar’s toughness 6-fold,” the authors write in the conclusions of their work. The first property — strength — is expressed in gigapascals, the unit of pressure. For comparison, the first nylon patented (not invented) by chemical giant DuPont almost a century ago had a tensile strength of 0.08 GPa, although current versions have greatly improved. The other property — toughness — is expressed in joules per cubic meter. The value achieved by spider silk is one of the highest ever recorded for a fiber, either synthetic or man-made.

In a press release, the lead author of the study, Junpeng Mi, a researcher at the Faculty of Biological Sciences and Medical Engineering at Donghua University (China), argued that spider silk is “a strategic resource in urgent need of exploration.” For Mi, this material could have a wide field of applications, starting with medicine. “This type of fiber can be utilized as surgical sutures, addressing a global demand exceeding 300 million procedures annually,” he said.

Spider silk fibers could also have applications in clothing with new properties, bulletproof vests, smart materials, aerospace technology and biomedical engineering. The key, he said, is to take what they achieved with a few worms in the laboratory, and scale up the process.

“Silkworm silk is presently the only animal silk fiber commercialized on a large scale, with well-established rearing techniques,” said Mi. “Consequently, employing genetically modified silkworms to produce spider silk fiber enables low-cost, large-scale commercialization.”

One possible obstacle, however, is cost, according to Gustavo Plaza, a professor at the Polytechnic University of Madrid (UPC). “Technically, it is viable and could be commercially viable, but we would have to look at the cost compared to that of synthetic fibers,” said Plaza, who has studied both synthetic materials and various kinds of spider silk and silkworm fiber.

The Spanish researcher agrees with Mi that spider silk “combines the best of fibers such as nylon and Kevlar.” He explains that spiders produce up to seven different types of silk. “The best threads are those from the spokes of their cobwebs,” he said. But the spider’s system for secreting its silk is as sophisticated as the silkworm’s process. So much so that humans have not been able to replicate it. “We have dissolved the silk and using those same proteins to spin it again has not given it the same properties. We haven’t been able to copy spiders or silkworms,” he explained.

A decade ago, another attempt was made to get worms to make spider silk. The researcher behind that effort was Randy Lewis, a recently retired professor at Utah State University in the United States. Lewis — who did not take part in the study published in Matter — says the Chinese scientists have made two important advances.

“The first is that they have identified the fundamental protein structure of the silk fiber and what makes it strong,” he explained. “The second thing is that they have created silkworms that produce the spider silk protein in the cocoon fiber instead of the silkworm protein. The latter is what differentiates this work from others. In previous studies [like the one Lewis carried] there was always some silkworm protein present in the fiber.”

Lewis agrees with Plaza and Mi that “with this process, it is clearly possible to produce spider silk fibers on a large scale.”

Sign up for our weekly newsletter to get more English-language news coverage from EL PAÍS USA Edition

Tu suscripción se está usando en otro dispositivo

¿Quieres añadir otro usuario a tu suscripción?

Si continúas leyendo en este dispositivo, no se podrá leer en el otro.

FlechaTu suscripción se está usando en otro dispositivo y solo puedes acceder a EL PAÍS desde un dispositivo a la vez.

Si quieres compartir tu cuenta, cambia tu suscripción a la modalidad Premium, así podrás añadir otro usuario. Cada uno accederá con su propia cuenta de email, lo que os permitirá personalizar vuestra experiencia en EL PAÍS.

¿Tienes una suscripción de empresa? Accede aquí para contratar más cuentas.

En el caso de no saber quién está usando tu cuenta, te recomendamos cambiar tu contraseña aquí.

Si decides continuar compartiendo tu cuenta, este mensaje se mostrará en tu dispositivo y en el de la otra persona que está usando tu cuenta de forma indefinida, afectando a tu experiencia de lectura. Puedes consultar aquí los términos y condiciones de la suscripción digital.