The tailors of Burgos take on the couturiers of Milan

Founded in Briviesca in 2011 by five locals, the Antonaga label makes more than 5,000 suits a year

Briviesca doesn't have much in common with Milan, the fashion capital of Europe. Nonetheless, the Italian city’s outfitters are no match for five men from this small town of around 7,000 in the northern province of Burgos.

In 2012, the five set up Antonaga, a suit-maker that deals predominantly in bespoke tailoring. With a presence in more than 300 Spanish and Portuguese outlets, the team is now hoping to sell their product further afield.

It all started back in 2011, when a textile company called Confecciones Cardenal employing a staff of 200 could no longer compete with countries such as China and closed the doors of its four-story building on Briviesca’s Avenida de Príncipe de Asturias. As if to remind locals of who sunk the ship, the bottom of the empty building houses a Chinese bazar.

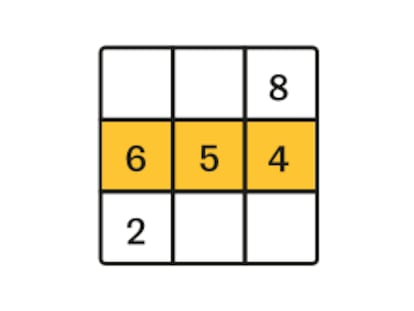

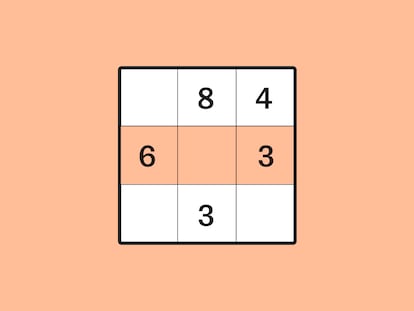

Antonaga hopes to have sold as many as 6,000 suits by the end of the year – up from 2,500 in 2012 – and register a turnover of €1.2 million for 2016

But from the ashes of Cardenal rose Antonaga. Five of the redundant staff, Ángel Ruiz and his son Jorge, José Antonio Aparicio, José Antonio Brunet and Alberto Martínez decided to turn their experience and contacts to their advantage and bought Cardenal’s machinery from the bankruptcy trustees and, with the help of family and friends, shifted it to a warehouse in a nearby industrial estate. Between the machinery, the warehouse and the refurbishments, they were looking at an investment of around €700,000.

“The move took about three weeks, using friends and family who took the machinery in their cars and tractors,” says Jorge Ruiz who is in charge of sales and marketing. “We did it all with our own money through personal loans and by mortgaging our homes and borrowing money from our families.”

Business got off to a flying start. While they were still installing the machines in the new premises, they made their first Antonaga suit for a groom in Toledo. It took just eight hours.

The company sells in Spain and Portugal and is set to expand into Switzerland, France and Holland

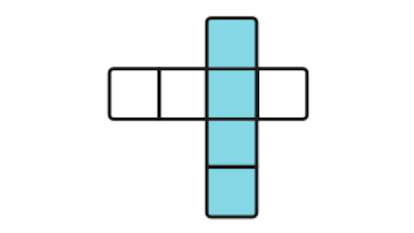

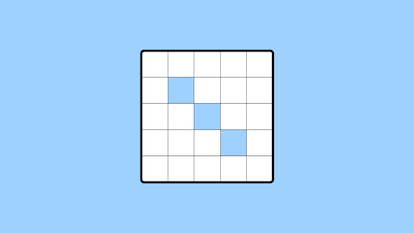

A 130-piece jigsaw puzzle

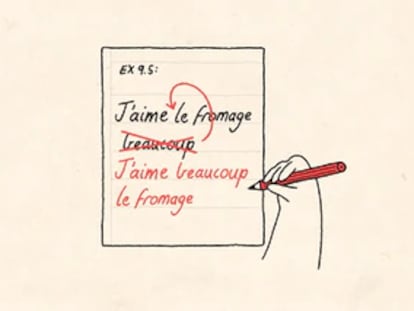

Believe it or not, making a suit involves putting together as many as 130 pieces – the jacket has 80 and the trousers 50. The process in Antonaga begins when Jorge Ruiz hangs up the phone or receives an e-mail with the customer’s measurements and other specifics. The order is then turned into a pattern by José Antonio Brunet and the flimsy pieces of pattern paper are pinned to the fabric. The next step involves cutting the fabric around the paper pattern, either with scissors or with a machine that requires the use of protective metallic gloves to feed the material through.

“It’s important to respect the print of the fabric when cutting it – whether it’s checked or striped – so that later the pieces match up,” says Alberto who adds that almost 20% of the fabric ends up in the bin.

Once the pieces are cut and numbered, they are subjected to temperatures of 130 ºC for several seconds to avoid shrinkage later on when the suit is taken to the dry cleaners. The pieces are then laid in two piles – the trouser pieces in one and the jacket pieces in the other.

The front panels and back, the pockets and neck and buttons … bit by bit, the tailors stitch them all together, tacking them so that the different layers remain in place when they are machine-stitched, and remembering to leave a little room for growth. Pressing the suit is then done in stages to give it shape. Once it has been through all this, it ends up in the hands of José Antonio Aparicio who adds the arms – a crucially important part of the process. “You can really see if it’s not done well,” says José Antonio.

Finally, the tacking is taken out and the suit gets pressed. Jorge himself then picks the suit off the hanger and sends it to the customer.

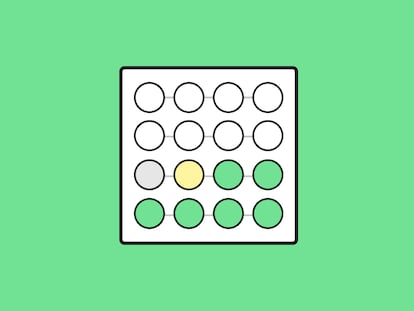

In the first year, the five partners worked with three employees. Four years later, Antonaga has 32 employees – 24 of which are women – almost all of whom worked at Cardenal.

“We’re really pleased to be able to offer jobs to our old workmates from Cardenal,” says Alberto who worked for the textile firm for 18 years.

Antonaga hopes to have sold as many as 6,000 suits by the end of the year – up from 2,500 in 2012 – and register a turnover of €1.2 million for 2016. Already they have opened a new storage warehouse and offices as well as a show room. But there is no need to go to Burgos for an Antonaga suit. Not only are they available for order across Spain, they could soon be moving into markets in Holland, France and Switzerland, with the help of Spain’s export and investment service ICEX.

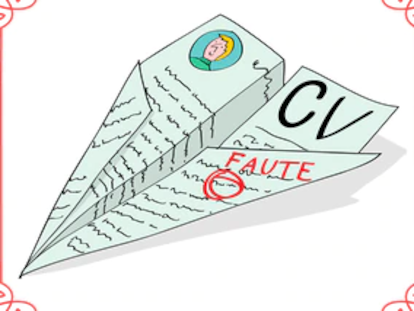

Such is the runaway success of the outfitters, in 2015, it won the IFEMA prize for the best small business in Spain and the business newspaper Expansión awarded them for creating employment. But they’re not millionaires yet. “We can’t talk about profits yet,” says Alberto, “because all the profits go back into the business.”

In fact, unbridled expansion is definitely not part of the gameplan. “Ideally, we will turn out 60 suits a day and reach a ceiling of 15,000 a year, “ Alberto adds. “We couldn’t ensure the quality if we made more and quality is what we care about.”

Alberto is echoing the philosophy of partner José Antonio, the house cutter with 40 years of experience behind him. He hand stitches the sleeves of the suits before they are sewn by machine. “The strategy is to be exclusive. It’s what makes us different,” he insists.

When they started out, less than half of the suits bore the Antonaga label. Tailors across Spain would take their customer’s measurements and Antonaga would run up the suits. Today, 95% of the clothes bear the label or at least one that reads “Antonaga made for…”

Sign up for our newsletter

EL PAÍS English Edition has launched a weekly newsletter. Sign up today to receive a selection of our best stories in your inbox every Saturday morning. For full details about how to subscribe, click here

Some of the credit for this is due to the other José Antonio, the pattern designer who not only takes down the measurements but other instructions as well, such as how the suit should hang from the shoulder. “We also use good fabrics,” says Alberto who oversees this department. “70% are Italian, like Vitali Barberís Canonico or Angelico, but there are English, French and Spanish fabrics too. We go to the Milan fabric fair twice a year. The thread used is German and selected for its durability.”

Along with his partners, José Antonio works hard, aware that he is keeping his trade alive. With an eye on the future, he is also focused on passing it on to the next generation and has already hired two promising youngsters for an apprenticeship.

English version by Heather Galloway.

Tu suscripción se está usando en otro dispositivo

¿Quieres añadir otro usuario a tu suscripción?

Si continúas leyendo en este dispositivo, no se podrá leer en el otro.

FlechaTu suscripción se está usando en otro dispositivo y solo puedes acceder a EL PAÍS desde un dispositivo a la vez.

Si quieres compartir tu cuenta, cambia tu suscripción a la modalidad Premium, así podrás añadir otro usuario. Cada uno accederá con su propia cuenta de email, lo que os permitirá personalizar vuestra experiencia en EL PAÍS.

¿Tienes una suscripción de empresa? Accede aquí para contratar más cuentas.

En el caso de no saber quién está usando tu cuenta, te recomendamos cambiar tu contraseña aquí.

Si decides continuar compartiendo tu cuenta, este mensaje se mostrará en tu dispositivo y en el de la otra persona que está usando tu cuenta de forma indefinida, afectando a tu experiencia de lectura. Puedes consultar aquí los términos y condiciones de la suscripción digital.