From field to bag to bowl: how Florette prepares your bagged salad

Firm that introduced pre-packed greens to Spain also exports to UK and McDonalds’ France

Each day, Florette Ibérica gathers its raw material and, almost immediately, chills it so it can be moved to a processing plant in a cold-storage truck that maintains it at a temperature of no more than 4ºC. Once there it is cut, washed, dried and bagged. This is how the company, the first to produce bagged salad leaves in Spain, prepares its products at its Milagro plant in Navarre, the first of five it has built around the country since 1989.

The company was founded under the name Vega Mayor in Milagro. It started out with just 40 employees, and now employs more than 1,300. In 2001, it was bought out by French firm Florette, and now produces 450,000 bags of salads and greens a day to be sold in more than 7,000 shops in Spain and Portugal. In 2014, turnover reached €138 million, and it sold around 41,000 tons. The secret of its success lies in two factors: coolness and speed.

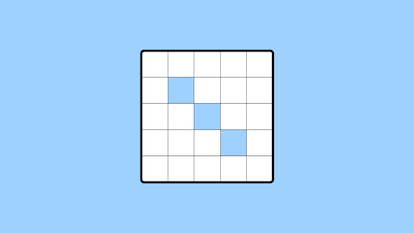

After the greens are picked, they are transported to the Vacoom, which lowers their temperature to around 4ºC

Aside from its production plant in Navarre, the company has installations in Cuenca, Toledo, Murcia and the Canary Islands, allowing it to cover all Spanish territory. “All our plants are located a few kilometers from the fields where we grow our vegetables, so that the raw material arrives there and thus to the customer as quickly as possible and stays fresh,” says Javier Les, technical director of Florette Agrícola, the division that grows and collects the different salad leaves and greens. “This is how we guarantee the quality of our products.” The company has around 1,800 hectares under cultivation, and produces 39,000 tons of salads and greens a year.

Its products fall into two categories: mature-leaf salads – such as lettuces, curly endives and greens – and baby-leaf salads, introduced into Spain by Florette. The former are grown outdoors, while baby-leaf salads are cultivated in plastic-sheeted greenhouses. “The baby leaves are more delicate, we might say they are the essence of the plant. When we started with them 10 years ago we didn’t know much, we were the first, and we have learned more over time,” says Les. In total, the company has 1,400 hectares of mature-leaf salads under cultivation in Spain, and almost 400 hectares of baby leaves.

The characteristics of our product oblige us to meet a daily supply. We work under intense time pressure” Florette commercial director Fermín Aldaz

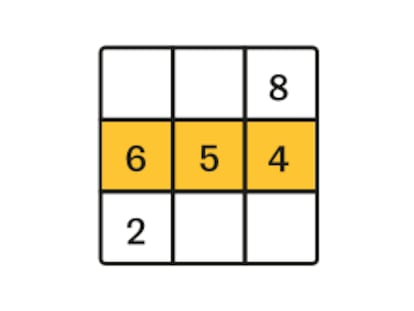

Just five kilometers from the Milagro plant are Florette’s farms. The company has around 500 hectares under cultivation in the area. After the greens have been picked, a cold-storage truck transports them a few hundred meters to the Vacoom, a machine that lowers their temperature to around 4ºC. Once the merchandise is ready, a cold-storage truck takes it to the plant.

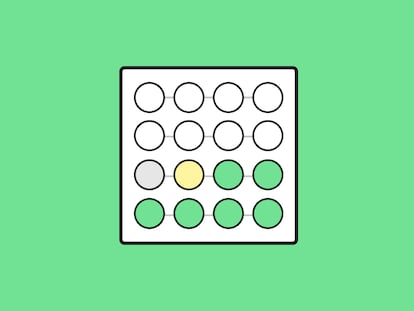

“The only way to keep the product fresh is by keeping it cold,” says Iker Jaunsaras, manager of the Milagro plant. When the raw material arrives at the production plant, it is bagged within 15 minutes and is then ready to be sent out to customers.

“The characteristics of our product oblige us to meet a daily supply, therefore we have to work on a daily basis,” says Fermín Aldaz, the company’s commercial director. “We work under intense time pressure.”

Florette’s Spanish production centers have to estimate what the market will want that day. Salads and greens are picked in the early morning and reach the plant by 8am. When the orders begin to come in a few hours later, the bags need to be ready to leave the plant.

The Milagro installations are like a giant kitchen, albeit a very cold one. The process seems simple enough, and is pretty much what anybody would do at home with fresh vegetables. They are cut, washed, dried and bagged. “This all used to be done by hand, but over time we have increasingly automated it, so there are a lot more machines around,” says Marisol Serrano, a 20-year veteran of the company who is in charge of the night shift at the Navarre plant.

Florette is constantly innovating. In 2014, it invested €2 million in new equipment, and this year intends to spend the same amount again. It employs a team of eight researchers to come up with new products, new categories and new markets. Around a third of sales comes from the launch of new varieties.

All our plants are a few kilometers from the fields, so that the raw material arrives there as quickly as possible and stays fresh” Javier Les, Florette Agrícola technical director

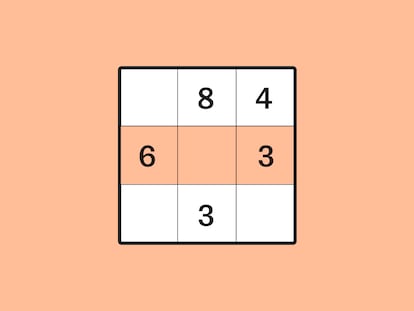

This year, Florette will be focusing on a new product line of prepared meals, an area that is growing 70 percent annually. The company has invested €1 million to expand its installations at its Navarre plant to make these products, which consist of a plastic tray divided into two parts, one containing a salad and the other chicken and pasta. The company aims to produce around seven million units a year.

“When we started we launched a product that met the needs of customers by being healthy and easy to use. We introduced a new way to eat salads. Over the years, we have developed different raw materials such as rocket and lamb’s lettuce. In this latest phase, with prepared salads, we want to boost consumption with our new full menus,” says Jaunsaras.

Florette Ibérica exports 20 percent of its production. “Our main customer is McDonald’s in France: we export around 8,000 tons a year to them, but we also sell to Portugal, and seasonally to the United Kingdom,” explains Aldaz.

The prepared salads are difficult to export, he says. “They have a very short shelf life, and once processed, the logistics are expensive. What’s more, our group is present in different countries with the same strategy as Spain to cover those markets,” notes the commercial director.

Tu suscripción se está usando en otro dispositivo

¿Quieres añadir otro usuario a tu suscripción?

Si continúas leyendo en este dispositivo, no se podrá leer en el otro.

FlechaTu suscripción se está usando en otro dispositivo y solo puedes acceder a EL PAÍS desde un dispositivo a la vez.

Si quieres compartir tu cuenta, cambia tu suscripción a la modalidad Premium, así podrás añadir otro usuario. Cada uno accederá con su propia cuenta de email, lo que os permitirá personalizar vuestra experiencia en EL PAÍS.

¿Tienes una suscripción de empresa? Accede aquí para contratar más cuentas.

En el caso de no saber quién está usando tu cuenta, te recomendamos cambiar tu contraseña aquí.

Si decides continuar compartiendo tu cuenta, este mensaje se mostrará en tu dispositivo y en el de la otra persona que está usando tu cuenta de forma indefinida, afectando a tu experiencia de lectura. Puedes consultar aquí los términos y condiciones de la suscripción digital.